Driveway Address Sign - VOTE!!

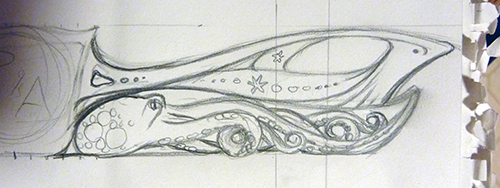

We’re planning a bit of an elaborate house sign at the front of our driveway. I’ve done two design sketches which are shown below.

So my question is, which one do we build? Whichever gets the most votes is the one we build!(facebook, email or in the comments below)

Not much variation in the theme (sea creatures) but I will take your preferences into consideration when creating the final abomination such as; should it feature more eyeballs, or fewer eyeballs? More squamous and batrachian creatures or fewer? More amorphous, or more defined?