Chapter Two - The Pub

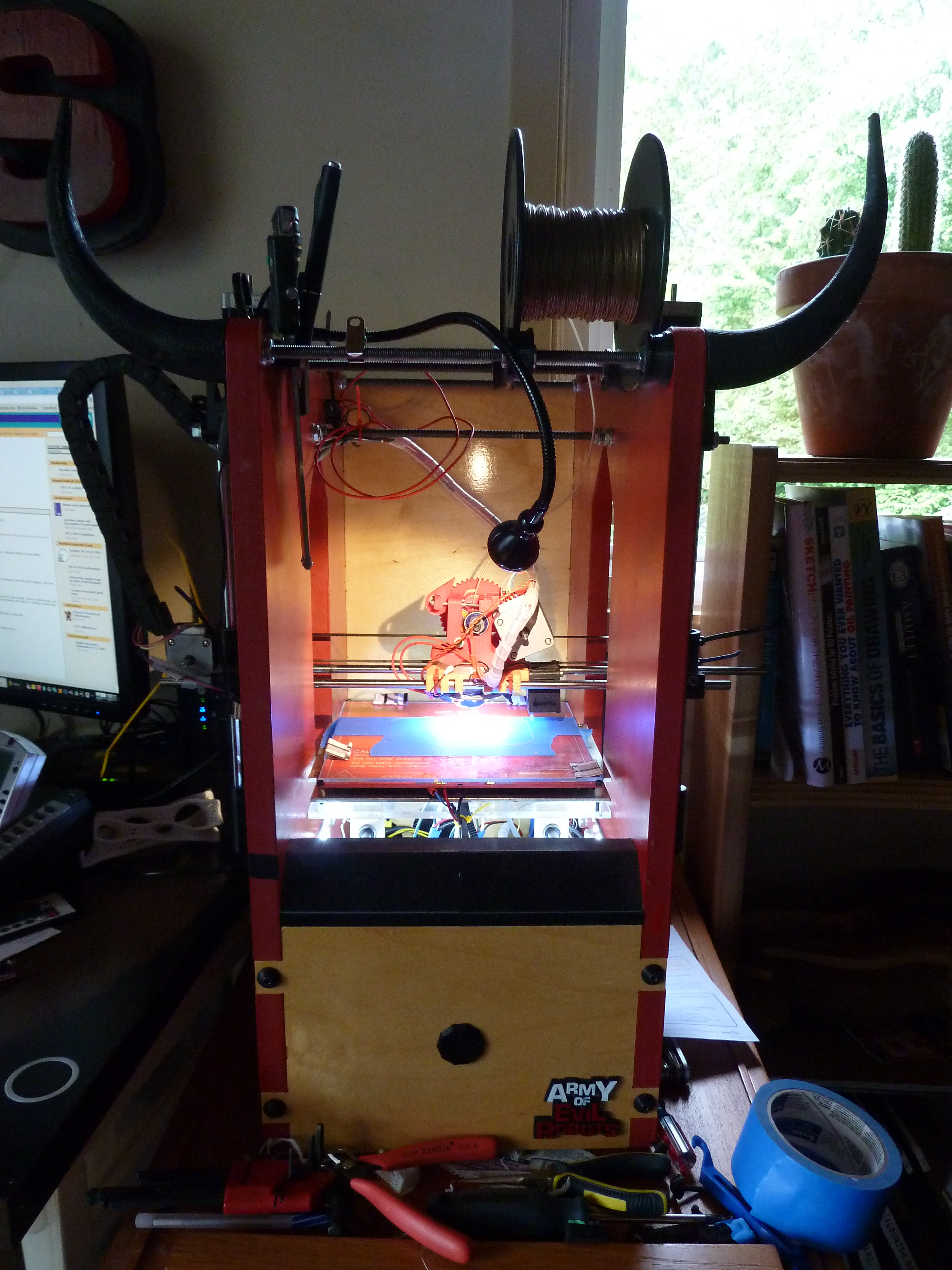

When I was a wee lass, perhaps 5 or 6 years old, my family took us for a camping trip in the English country side. The English weather lived up to its good name. It rained the entire time and the field was muddy. Before long, my wonderful father suggested the brilliant idea of taking me to a nearby pub. I realize now that it was probably at the request of my Mother, to get me out of her hair so that she could get the tent set up. (Thanks Mum) However, at the time, I just thought my Dad wanted to take me on a great adventure. My memory of that pub is as keen as if I was there yesterday. The worn wooden bar top, darts and snooker tables, footy on the telly, and the stench of stale beer soaked carpets …. in other words….paradise! I was perched up on a tall bar stool and given a strongbow to sip. Oh what heavenly nectar, sweet as a hummingbird’s kiss! I was done with camping, this was what life was all about. It made an indelible mark on my young mind and since then, it’s been my lifelong dream to have my own private pub in my own house. Well, now we do, complete with plumbed in kegs. Here’s Derek pouring a pint: