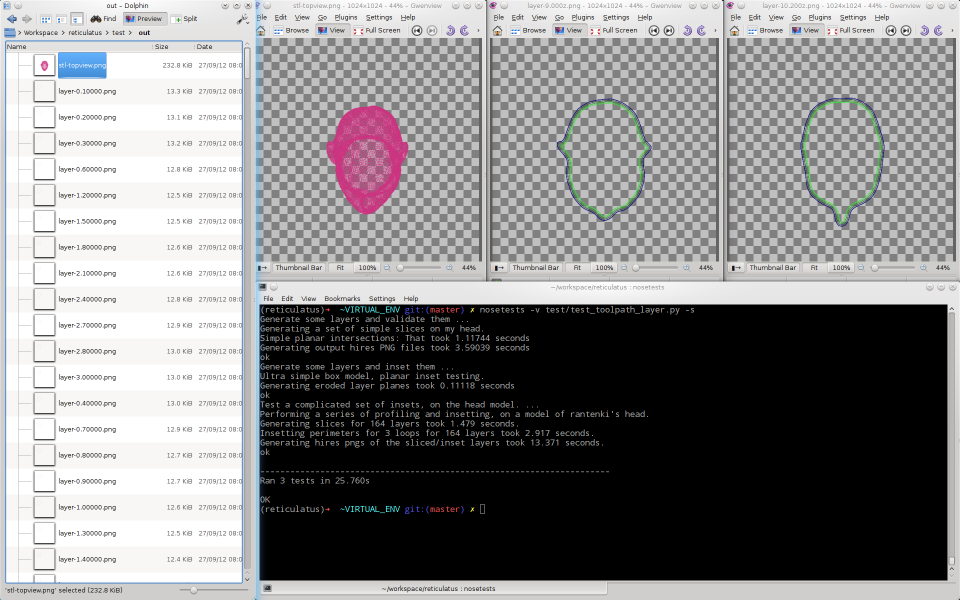

Reticulatus Improvements

I have added some updates to Reticulatus which vastly improve the OpenGL display window. Now I am ready to start adding slicing tools to the UI.

[youtube http://www.youtube.com/watch?v=4cn2QE-PHxA&w=853&h=480]

I have added some updates to Reticulatus which vastly improve the OpenGL display window. Now I am ready to start adding slicing tools to the UI.

[youtube http://www.youtube.com/watch?v=4cn2QE-PHxA&w=853&h=480]

Python based 3d printer slicers need to be faster: rantenki/reticulatus.

[youtube http://www.youtube.com/watch?v=mE1XwmJm848&w=853&h=480]

It should be noted that this has no interface, no gui, not cmdline, and cannot yet be used for slicing unless you call the libraries directly from python.

That is all.

Went to Greendale Pottery and Beef yesterday to pick up a quarter of a cow. You heard me. A quarter of a freakin’ cow.

What? It’s Barbecue season?

Anyway, as I’m sure you’ve gathered from the name, she also makes amazing pottery. Check out our new pottery beer mugs. Looks like a beer poured into a clear glass and running down the edges but it’s just the glaze colour.

ps. Maker Faire on Saturday! Don’t forget to buy tickets!

I have been having some issues with insufficient bed adhesion, especially when using some less than stellar PLA, so started experimenting with a variety of bed treatments. ABS paint, bluetape and Kapton all worked pretty well, but the new, all time champion is now PVA/Weldbond glue in an ultra-thin layer, only a few molecules thick, which gets the strongest (perhaps too strong) bond I have ever managed. This thin layer completely eliminates any corner lift, and prevents the tape from being pulled off of the bed as well. As a bonus, the heated bed doesn’t have to run as hot.

Here’s a brand new clock we’re in the middle of making. The top shows the design, below that are a few snapshots of the first two layers cut. The base layer is a 2 inch thick slab of walnut, next is the maple, the top layer will be tigerwood. That’s the orange top part in the drawing. We will be cutting the tigerwood this afternoon. We’ll bring is along to Maker Faire in whatever stage of completion it happens to be. This one is much bigger than our first clock, measuring about 2ft wide….working our way up to a grandfather clock.

Well the pub sign is finally done! We’ll be bringing it to Maker Faire this year but it’s final home will be above our kegerator beside the bar.

We cut the sign on our big CNC from scraps of HDU (High Density Urethane) kindly given to us by Dan Sawatsky of Imagination Corporation. Dan is pretty much the world’s greatest sign maker and a huge inspiration.

Phew! I think it’s time for a beer.